technology

The company equipment consists of vertical and horizontal traditional lathes for roughing. However M.L.M. has also CNC lathes and CNC boring machines combined with the latest machining softwares to perform shaped pre-finished and finished profiles, drillings and threadings.Difficult machinings are simulated starting from a 3 D item model by the latest version of CAD CAM softwares in the technical office.

The company has been also beginning to apply the Industry 4.0 principles in the workshop by replacing technical papered documents and written data. Data are always collected to monitor, to maximize and to plan production and maintenance with modern MES softwares , tablets and touchscreen computers connected to the company network. Technology, however, comes together with the need of constantly train the personnel which is one of the principles M.L.M. deeply believes in.

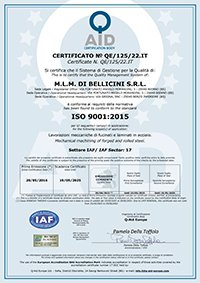

quality

For M.L.M. quality always means accuracy, working rapidity, respect of delivery due dates and attention to customer requests and expectations.

Find out more